Project RoX

A Fusion of AI and Robotics: A Glimpse into the Future

In the not-so-distant future it is envisioned that robotic solutions will become as flexible as humans. Humans will be able to delegate any annoying job to a robot. This will enhance productivity in the work environment and thus reduce the overall workload on human workers leading to a better work-life balance and creating a better workplace. While the automation of routine work is at the state-of-applied technology artificial intelligence is expected to be key in enabling the required flexibility of future automation. In response to these challenges, INVITE along with 24 partners including ABB, DLR, Fraunhofer, Gluth Systemtechnik, RIF, and Roboception are collaborating on Project RoX. Project RoX aims to establish a decentralised Data and Service ecosystem that also supports the development of AI enabled automation through robotics in the areas of production and logistics.

RoX is funded by the Federal Ministry for Economic Affairs and Climate Protection with DARP funds based on a decision by the German Bundestag and financed by the European Union – NextGenerationEU. The aim of NextGenerationEU is to achieve a stronger and more resilient Europe by focusing their investments on healthcare, education and skills, SMEs and young entrepreneurs.

INVITE is especially well suited for this project with its expertise in both pharmaceuticals and research in advanced automation and robotics technologies. Furthermore, INVITE offers equipped industrial grade research laboratories replicating real-world conditions, enabling the safe handling of hazardous materials compliant with industry standards.

The focus of INVITE in this project is in two areas of application:

- Mobile flexible Lab Robotics

Modern laboratories have workers executing highly specialized tasks under a controlled environment. However, equipment and protocols vary between experiments and people on a regular basis. This variability therefore produces a constant need for human supervision when performing an experiment, thus making working hours more demanding and prolonged, often on tasks that are menial. Moreover, some laboratory environments have workers exposed to hazardous substances, currently which are mitigated by stringent operating procedures.

One application currently being studied at INVITE is the handling of hazardous dry compounds. This presents significant challenges, not only due to the health risks posed by airborne particles – which can be highly toxic if inhaled – but also in ensuring precise measurement, contamination free-handling, and maintaining a safe working environment. Furthermore, preventing cross-contamination both in the surrounding areas and within the robot system itself is also critical. To address these challenges, INVITE is testing methods using a mobile robot to not only achieve accurate measuring without human intervention, but also to verify that the workspace remains uncontaminated after the robot completes its operation, ensuring both safety and compliance with laboratory standards.

2. Manual Cleaning of Parts

In the chemical-pharmaceutical industry in particular, all system parts that come into contact with products must be cleaned every time the product is changed. If this cannot be done within the system (cleaning in place), they have to be handled individually by hand during cleaning. These activities are not only some of the most unpleasant in operation, but also significantly restrict OEE (Overall Equipment Efficiency) optimization due to the lack of scalability and limited reliability. The variety of parts is enormous (~1000 per plant).

For this reason, production companies, like Bayer and Boehringer-Ingelheim, have a strong desire for automated systems to replace this manual cleaning process. For some time now, however, the relevant regulatory authorities - such as the European Medicines Agency, the FDA in the USA, the TGA in Australia or the HS-SC in Canada - have also been calling for automated solutions due to the constantly deteriorating hygiene situation in manual cleaning.

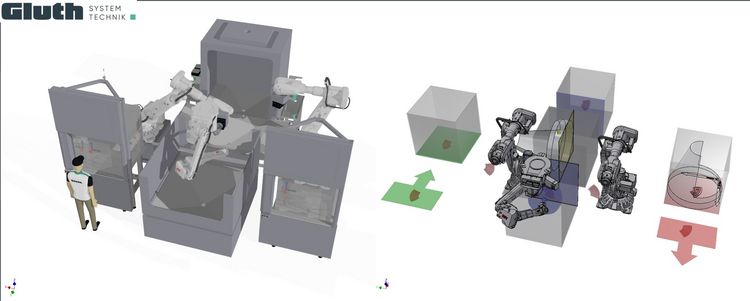

INVITE is supporting Gluth Systemtechnik in developing such an automated system (Figure 2) that minimizes human exposure in the cleaning process, while maintaining a reliable and repeatable throughput. The picture above shows the current system sketch with the receiving station for the parts delivered in trays, which are then recognized, gripped, cleaned, dried and discharged. All this is done not just safely and reliably, but with a qualified and documented cleaning process.

As Project RoX continues to progress, the use of automated solutions in production workflows promises to not only reduce the burden on human workers, but also address key challenges in efficiency, safety and scalability. By leveraging advanced technologies, such as robots or advanced AI models developed by our project partners, and with continuous optimisation of these solutions, adaptability to different environments is closer than ever, enabling for broader adoption of these automated systems.